27 March 2020

How to Maximize Safety and Minimize Incidents During Spring Break-up

Spring break-up — that lovely time of year when freeze-thaw cycles abound, transforming what was...

Paradox's Blog is a hub for thought leadership in the areas of construction, engineering, project management, leadership, and business in the civil construction and geotechnical engineering industries.

11 October 2019

Winter is coming... along with extreme weather and environmental conditions, which can greatly impact the productivity of companies with labour-intensive, outdoor operations. And although no one can control Mother Nature, we all have control over how we prepare for these types of conditions.

Being prepared for winter conditions can increase worker efficiency and decrease the likelihood of workplace accidents and injuries. Business owners, project managers, site supervisors, and crew members all benefit from collective efforts to adequately prepare their worksites and their crews for winter conditions.

When it comes to preparing your crew for winter working conditions, there are three key environmental factors to be aware of: air temperature, air movement, and humidity.

When it comes to preparing your crew for winter working conditions, there are three key environmental factors to be aware of: air temperature, air movement, and humidity.

Did you know: According to the Canadian Center for Occupational Health and Safety, water conducts heat away from the body 25 times faster than dry air.

These environmental factors can typically be counterbalanced with proper insulation, physical activity, and a balanced work/rest schedule (among other winter preparedness practices, as we cover further down in this article). Failing to properly prepare for cold weather work puts workers at a higher risk for cold stress and related illnesses and injuries.

Cold stress generally refers to cold-related illnesses and/or injuries a person may suffer when they can no longer maintain a normal internal body temperature. Frost bite and hypothermia are among the most common consequences of cold stress.

Not all PPE is created equal. Clothing should be selected to suit the temperature, weather conditions, intensity and duration of activity, and job design.

Working in cold temperatures demands more energy than working in warm weather for two key reasons:

Early symptoms of cold-related illnesses — especially hypothermia — can be subtle and difficult to recognize in/on yourself. Work in pairs to help spot warnings signs such as confusion and sluggishness.

Anyone involved in cold-weather work should know how to identify and manage symptoms of cold-related injuries and illnesses. They should also be informed about appropriate clothing and PPE, safe work practices, fitness requirements, and emergency procedures.

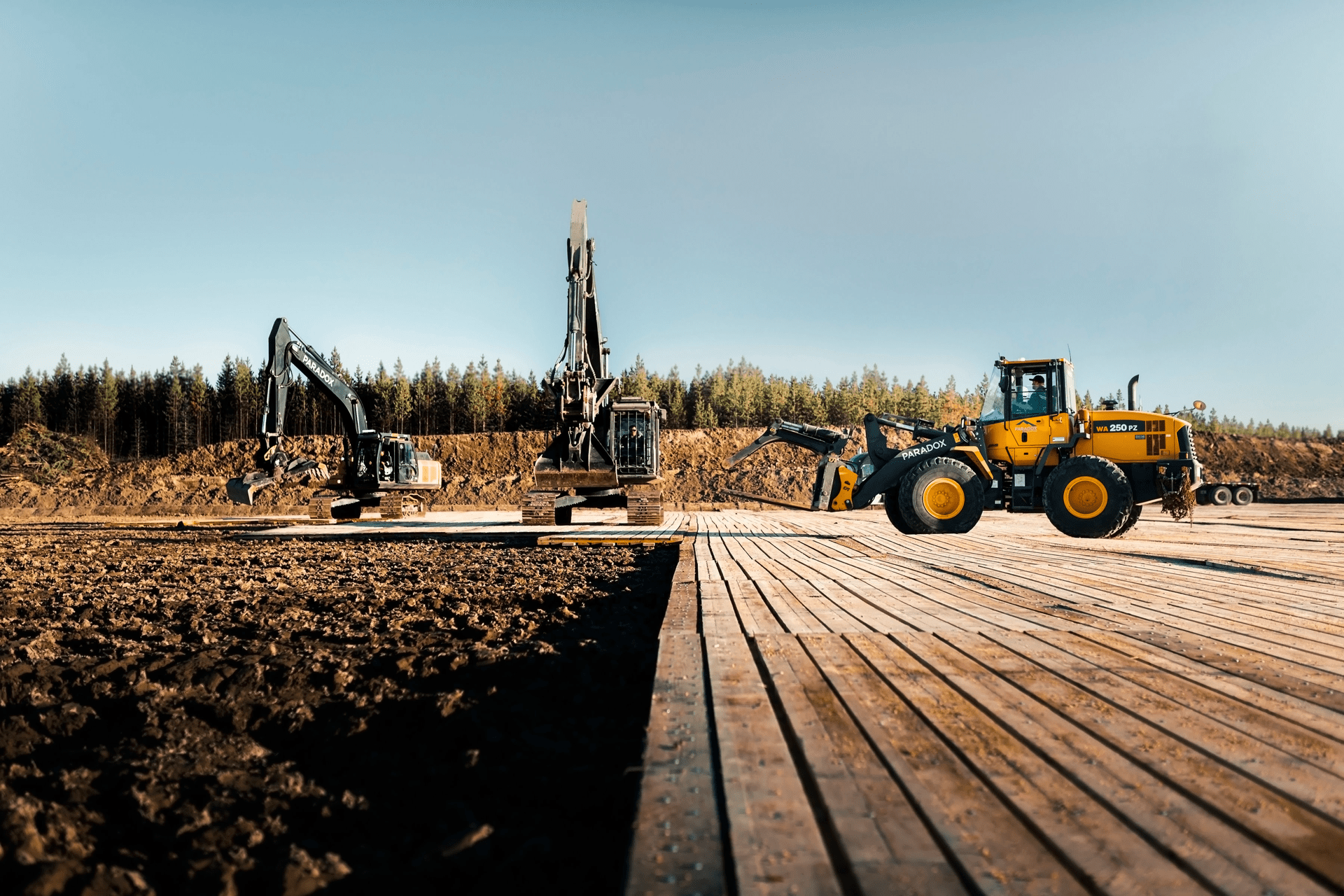

Preparing your workers is only one of many important preparation procedures that should take place as winter months approach. Equally as important is preparing your work site and equipment to accommodate winter work and personnel because no matter how dry, warm, fed, and hydrated your workers are, if your job site isn't adequately set up for the season, they still face great risk of injury to themselves and others.

In addition to preparing your worksite ahead of time (site prep usually begins in August), the following precautions are advised:

Make sure expectations on the job site account for added bulkiness and weight of winter clothing and PPE, as well as extra time that may be required to ensure workplace safety. Hiring a snow removal service to snow removal and deicing can help mitigate workers' risk of overexertion.

As much as possible, keep walkways and working surfaces at grade to help avoid the risk of slips and falls on slippery surfaces. Cover all cords and cables that cross walkways, and make sure all mats are laid flat and secured appropriately. Monitor and mop any spills or wet floors, which are especially common as workers flowing in and out of buildings can easily bring snow in with them.

Also keep in mind that daylight hours are significantly reduced during winter months, so visibility may be suboptimal. Ensure your worksite is equipped with adequate lighting so that workers can safely perform their duties.

Cover metal handles and bars with thermal insulating material and ensure all machines and tools can be easily and safely operated while wearing mittens or gloves. Train your crew for operating equipment and driving vehicles in winter conditions, and ensure all operators are properly licensed.

If your crew will be working in below-freezing conditions, heated warming shelters such as tents or cabins should be made available, and an appropriate warm-up break schedule encouraged.

Additionally, work should be paced to avoid excessive sweating, as damp/wet clothing can be a catalyst for cold stress and related injuries and illnesses. If this type of intense physical labour is absolutely necessary, make sure your workers are given proper rest periods in a warm area and have them change into dry clothes.

The combined effect of these two factors is called "wind chill". Simply put, wind chill is the air temperature that would feel the same as the given combination of air temperature and wind speed and can be used as a guideline to help prepare for cold weather conditions.

It is a long established fact that a reader will be distracted by the readable content of a page when looking at its layout.

27 March 2020

Spring break-up — that lovely time of year when freeze-thaw cycles abound, transforming what was...

25 October 2019

While a fluffy layer of freshly-fallen snow can easily transform an average scene into an...